This article covers materials, design (pipe sizing) and installation of drainage system.

Drainage piping material

Drainage piping shall be cast iron, galvanized steel, galvanized wrought iron, lead, copper, brass, Schedule 40 ABS DWV, Schedule 40 PVC DWV, extra strength vitrified clay pipe, or other approved materials having a smooth and uniform bore, except that:

- No galvanized wrought iron or galvanized steel pipe shall be used underground and shall be kept at least 6 inches (152 mm) above ground.

- No vitrified clay pipe or fittings shall be used above ground or where pressurized by a pump or ejector. They shall be kept at least 12 inches (305 mm) below ground.

- Copper tube for drainage and vent piping shall have a weight of not less than that of copper drainage tube type DWV.

Drainage fittings shall be of cast iron, malleable iron, lead, brass, copper, ABS, PVC, vitrified clay, or other approved materials having a smooth interior waterway of the same diameter as the piping served and all such fittings shall be compatible with the type of pipe used. Fittings on screwed pipe shall be of the recessed drainage type. Burred ends shall be reamed to the full bore of the pipe. The threads of drainage fittings shall be tapped so as to allow 1/4 inch per foot (20.9 mm/m) grade. Fittings used for drainage shall be of the drainage type, have a smooth interior waterway, and be constructed so as to allow 1/4 inch (20.9 mm/m) per foot grade.

Ferrules and Bushings

Caulking ferrules shall be manufactured from bronze or copper and shall be in accordance with Table 7-1. Soldering bushings shall be of bronze or copper in accordance with Table 7-2.

Drainage pipe installation

Horizontal piping must be installed in alignment, parallel to walls and at sufficient pitch to ensure a minimum velocity of flow of 2 fps. To attain this minimum velocity for scouring action a minimum pitch of ¼ in./ft should be employed for all pipe 3 in. and smaller in diameter. A pitch of 1⁄8 in./ft for larger pipe is satisfactory to maintain an adequate velocity in the piping. Drainage 90° elbows, traps, sanitary tees, and tee wyes are all tapped at a pitch of ¼ in./ft to provide proper pitch to the horizontal pipe when transferring from the horizontal to the vertical position. Horizontal drainage piping should be so routed as not to pass over any equipment or fixtures where leakage from the line could possibly cause contamination. Drainage piping must never pass over switch-gear or other electrical equipment. Route piping around electrical closets. If it is impossible to avoid these areas and piping must be run in these locations, then a pan must be installed below the pipe to collect any water from leaks or condensation. Drain line is run from this pan to a convenient floor drain or service sink. Underground drainage piping should always be laid on a firm bed for its entire length with the earth scooped out at the bells to make this possible (See Figure 5-4).

Clean earth or screened gravel should be firmly tamped under, around, and above the pipe to a level of 1 ft above, and thereafter backfilling can be completed to grade, compacting the fill every 2 ft. Piping above-ground in the building should be securely supported from the building construction. Piping should never be hung from duct-work or other piping. Inserts, rods, hangers, piers, and anchors should be of durable material having adequate strength to perform their function. Maximum spacing between supports for various piping materials should be

1) Cast iron soil pipe

- Horizontal: at every fitting and every joint

- Vertical: at every story

2) Screwed piping

- Horizontal: every 12 ft

- Vertical: alternate floors

3) DWV copper

- Horizontal: every 10 ft for 2 in. and larger, every 6 ft for smaller sizes

- Vertical: every story

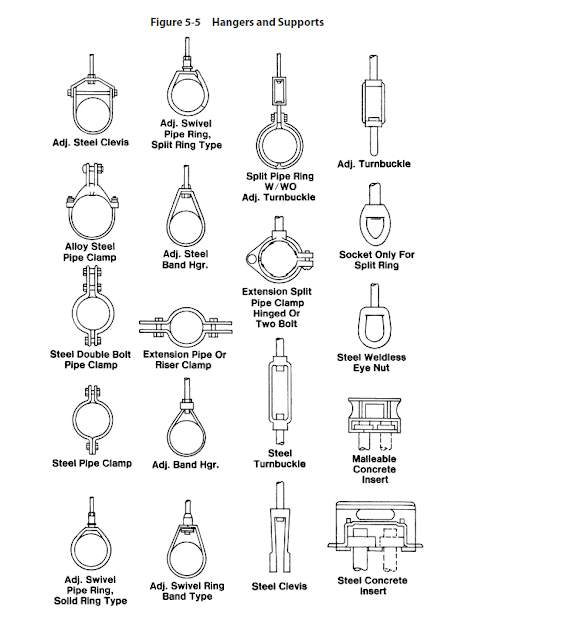

Figure 5-5 shows various hangers and supports for installation of drainage piping

Cleanouts

Each cleanout fitting for cast iron pipe shall consist of a cast iron or brass body, and an approved plug. Each cleanout for galvanized wrought iron, galvanized steel, copper, or brass pipe shall consist of a brass plug as specified in Table 7-6, or a standard weight brass cap, or an approved ABS or PVC plastic plug. Plugs shall have raised square heads or approved counter-sunk rectangular slots. Each cleanout fitting and each cleanout plug or cap shall be of an approved type. Materials used for cleanouts shall be conformed to approved standards acceptable to the Administrative Authority. Cleanouts shall be designed to be gas & watertight. Each horizontal drainage pipe shall be provided with a cleanout at its upper terminal and each run of piping, which is more than 100 feet (30480 mm) in total developed length, shall be provided with a cleanout for each 100 feet (30480 mm), or fraction thereof, in length of such piping.

Installation of cleanout

The installation arrangement of a cleanout shall enable cleaning of drainage piping only in the direction of drainage flow.

The rate of flow in a branch drain is obviously the sum of the flows from the fixtures connected to that branch. When the branch is of extended length (greater than 5 ft), to avoid the development of hydrostatic pressures at the required flow, the design of the branch is based upon the assumption that uniform flow conditions exist in the branch. Under no circumstances should the branch flow exceed the flow capacity of the stack or house drain to which it connects. The discharge of a branch into a stack should not cause excessive interference with the sheet of water flowing down the stack, or back-pressure in the branch could result. The maximum permissible flow capacity must be related to the probable simultaneous rate of flow in the stack. The maximum probable flow in the stack is a function of the total flow into the stack and the number of branches connecting into it. The average rate of flow from a fixture can be expressed fairly accurately by the formula

q = 13.17 d2 h½

where

q = Rate of discharge in GPM

d = Diameter of outlet orifice in inches

h = Mean vertical height of water surface above the point of outlet orifice in feet

Drainage Fixture Unit (DFU)

Drainage fixture unit is a quantity in terms of which the load producing effects on the plumbing system of different kinds of plumbing fixtures are expressed on some arbitrarily chosen scale. The fixture unit flow rate is the total discharge flow in gallons per minute of a single fixture divided by 7.5 (gal/ft3), which provides the flow rate of that particular plumbing fixture as a unit of flow.

Drainage stack pipe sizing method

Method for sizing a multistory stack is first to size the horizontal branches connected to the stack. This is done by totaling the fixture units connected to each branch and size in accordance with Table 6-4. Next, total all the fixture units connected to the stack and determine the size from Table 6-3, under the column “Stacks More than Three Stories in Height.” (The minimum size of the stack must be at least equal to the largest connected branch.) Immediately check the next column, “Total Discharge into One Branch Interval,” and determine that this maximum is not exceeded by any of the branches. If it is exceeded, the size of the stack as originally determined must be increased one size or the loading of the branches must be redesigned so that maximum conditions are satisfied.

Example of drainage pipe sizing

Section A >> 70 FU = 4 in

Section B >> 90 FU = 4 in

Section C >> 120 FU = 4 in

Section D >> 90 FU = 4 in

Section E >> 150 FU = 4 in

Section F >> 180 FU = 5 in

Section G >> 190 FU = 5 in

Section H >> 160 FU = 4 in

Section I >> 200 FU = 5 in

Size the portion of stack above offset should be done using Table 6-3

J = Sum of all branches connected to the portion of the stack above offset

A + B + C + D = 370 FU = 4 in

Immediately check last column of Table 6-3 to ascertain that total discharge into any one branch interval of a 4-in. stack is not exceeded. Branch C is 120 FU, which exceeds the limits of 90 FU and the 4-in. stack must therefore be increased to 5 in. so as not to overload that portion of the stack between branches C and D. Therefore stack J = 5 in

Size the offset using Table 6-5

Offset K = 370 FU = 5 in, (whether the slope is 1⁄8 in. or ¼ in.)

Size the portion of stack below offset should be done using Table 6-3

This equals the sum of all the branches, above and below the offset connected to the stack

A + B + C + D + E + F + G + H + I = 1250 FU = 6 in

Immediately check the last column of Table 6-3. The maximum permitted into any one branch interval of a 6-in. stack is 350 FU. This value is not exceeded and so Stack L = 6 in

Size the run out to the house drain using Table 6-5

M = 1250 FU = 8 in, (whether slope is 1⁄8 in. or ¼ in.)

0 Comments